This journal contacted Deepak Bawa, Director of Project Development with New Fortress Energy, to glean his observations on the potential role of hydrogen.

At room temperature and pressure, hydrogen is an odourless, colourless gas. However, read magazine articles and you will probably see hydrogen associated with a colour, such as grey, blue or green. This has nothing to do with added dyes, for the colours indicate the perceived environmental credentials of the gas. Grey hydrogen for example is mainly produced by reforming natural gas, a process which releases unwanted carbon dioxide into the atmosphere. If as part of that production process the carbon dioxide missions are captured and stored, then the hydrogen is said to be blue. An alternative production technique or hydrogen is electrolysis of water. If that electrolysis is achieved using emission-free electricity, such as generated by wind farms or solar parks, then the hydrogen is said to be green as no carbon dioxide is released during production. It is the blue and green forms of hydrogen that could therefore contribute to sustainable societies, says Mr. Bawa.

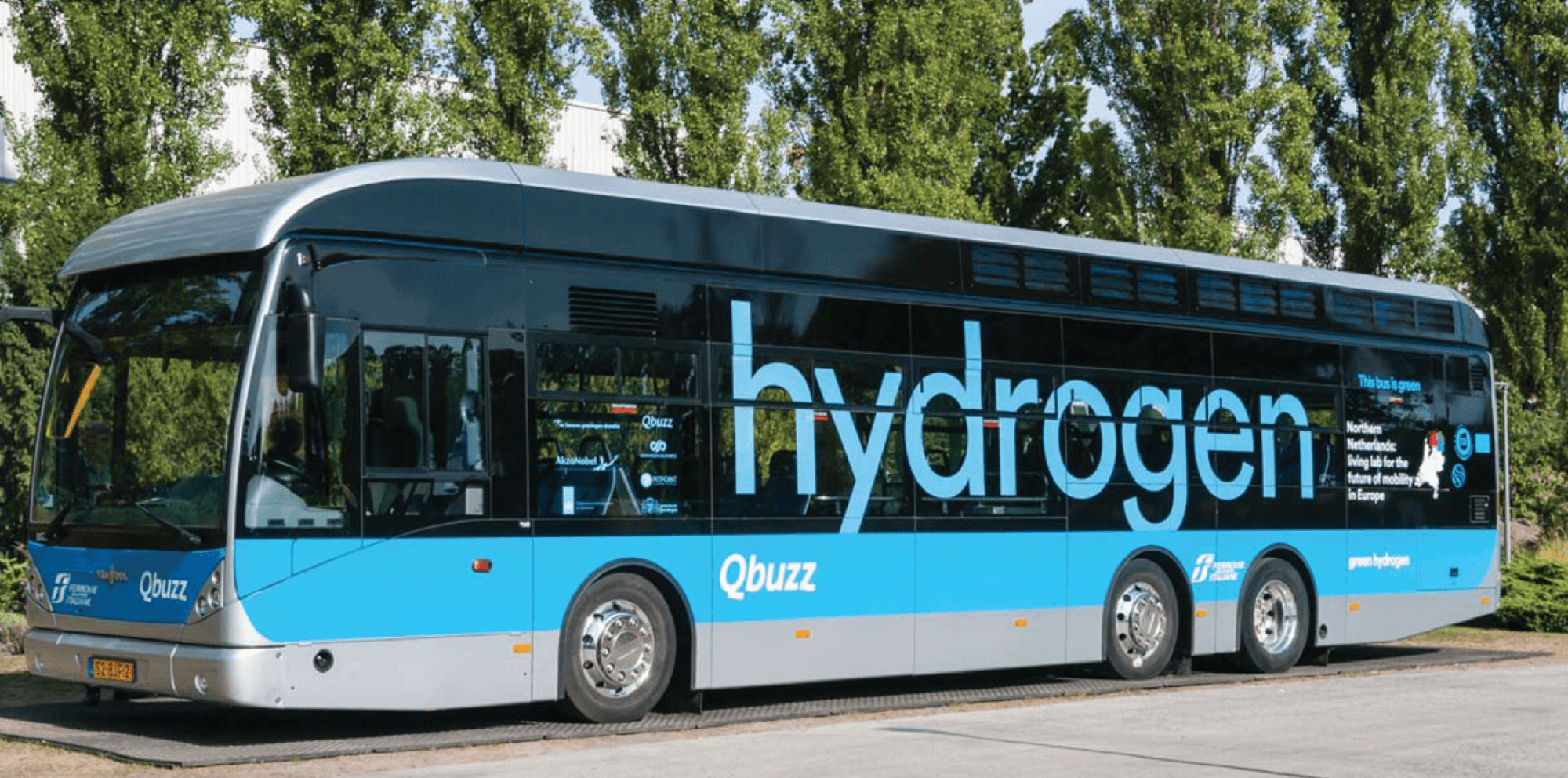

“Right now we are in the middle of an energy transition, and in this process I believe that hydrogen will play a crucial role,” opens Mr. Bawa. “Hydrogen has long been used as raw material in chemicals and refining and now many people see its potential as a clean fuel for both aviation and general transportation, as well as power generation, heating, etc.” In the ideal world, societies might wish to immediately switch to green hydrogen. However, given the need to first develop a green hydrogen infrastructure, and also bearing in mind the existing hydrogen production facilities, Mr. Bawa suggests a more balanced approach is called for.

“Of the three forms of hydrogen, blue is the most balanced option. Blue hydrogen can give us the energy source we need, at a realistic price, whilst avoiding the carbon emissions associated with grey hydrogen. Green hydrogen is, for the immediate future, still too expensive. That is why we need blue hydrogen in this energy transition.”

Hydrogen applications Worldwide, natural gas is of course used extensively as an energy source by both industry and households. It is praised by many for being a cleanburning fuel, but does release carbon dioxide into the atmosphere during combustion. Mr. Bawa therefore sees blue hydrogen as an ideal way to improve the environmental credentials of natural gas. “As we have captured the carbon during production, blue hydrogen could for example be mixed into the natural gas that is fed into our homes and factories to lower overall carbon dioxide emissions. In countries such as the UK this has already been successfully implemented.” Blue hydrogen can also be used to fuel

power plants.

NFE champions green energy

New Fortress Energy (NFE) envisions a world in which everyone, everywhere has access to affordable, 100% green energy. “Protecting our environment and expanding energy access shouldn’t be conflicting goals.

Our mission is to transform NFE into one of the world’s leading providers of carbon-free power by replacing fossil fuels with affordable green hydrogen,” states the company website.

To promote this goal, the company has set up a division with the apt name of ‘Zero’.

“In Ohio, for example, we are working with Long Ridge Energy Terminal to convert their 485 MW combined-cycle power plant to run on carbon-free hydrogen. The plan is to introduce up to 20% hydrogen into the gas stream by the end of 2021, and to slowly increase that to 100%

hydrogen. This is why I say that blue hydrogen and natural gas complement each other perfectly. I expect both will retain their existing roles during the coming ten to twenty years.”

Hurdles

Asked about challenges to the further introduction of blue hydrogen, Mr. Bawa first considers the financial aspects of carbon sequestration.

“Capturing and sequestering carbon dioxide currently costs around 65-70 USD per ton, yet the carbon tax credit paid for doing so is just 50 USD per ton. Hence the biggest challenge right now is helping companies balance their books. If the carbon tax credit were a little higher that would

certainly motivate the big hydrogen producers to install carbon capture systems.”

He gives a practical example of a hydrogen plant producing 50 metric tonnes per day. “Such a facility would have to spend 10-12 million USD to install carbon capture equipment. What incentive do they have to do that if the carbon tax credit paid out is too low for them to at least recoup

their costs? So two things have to happen – first the carbon tax credit has to go up, and second we have to further work on the technological side. Right now the amine technology is the best route to capture carbon, at least during the pre-combustion phase. Yet there is still much work to be done

to reach the goal of 100% carbon capture, especially during the actual combustion phase.”

An additional hurdle, continues Mr. Bawa, is the time required to obtain the necessary permits. Right now in the USA it can take up to 24 months for a company to hear if they can go ahead and build a carbon sequestration facility. If you are planning a greenfield development that is easy enough to factor in, but if you are looking to upgrade an existing plant you don’t want to have to wait that long.”

Government policies can do much to stimulate both blue and green hydrogen, believes Mr. Bawa. “Take the state of California, where officials recently announced the phase-out of cars running on gasoline or diesel by 2035. That is a huge opportunity and is one example of a market where hydrogen cars can be more successful. Right now the price for hydrogen fuel is 14-15 USD per kg.

If we can bring that down to around 5 USD per kilo then people really will have an economical as well as an environmental motive to buy a hydrogen car.”

At the end of our pleasant interview, Mr. Bawa states again how convinced he is of the potential for blue and green hydrogen. “Worldwide, there is a real and significant interest in hydrogen, with plans announced and engineering well underway. I expect that blue hydrogen will take the lion’s share of the market in the immediate future simply because it is more affordable. However, the price of green hydrogen will drop following technological advances in production as well as in the generation of renewable electricity. Fortunately the transition from blue to green hydrogen will be straightforward. A consumer who buys a hydrogen car will not notice any difference in performance if he switches from blue to green hydrogen. Both will give the performance he needs, without releasing harmful carbon into the environment.”

Materials considerations in hydrogen systems (gases & liquids)

- Generally acceptable materials for compressed hydrogen gas include austenitic stainless steels,

aluminum alloys, copper, and copper alloys. - Nickel and most nickel alloys should not be used since they are subject to severe hydrogen

embrittlement. - Gray, ductile, and malleable cast irons should not be used for hydrogen service.

- Designers of high-pressure hydrogen storage vessels and piping systems should understand

the effect of hydrogen exposure to materials (e.g., hydrogen embrittlement) in order to

make appropriate material selections. Note that certain surface finishing techniques (e.g.,

electro-polishing) and welding may introduce hydrogen into a metal, resulting in accelerated

embrittlement. - Ideally, testing (i.e., direct exposure of the material to hydrogen) and analysis should be done

to assure that the material will perform as expected at planned operating conditions as well as

worst-case conditions. - Material selection for liquid hydrogen service should be based on mechanical properties at the

low temperature (e.g., yield and tensile strength, impact strength). Industry typically uses the

Charpy impact test to determine the amount of energy absorbed by a material during fracture,

which is a measure of the material’s toughness. - Some materials change from ductile to brittle behavior as their temperature is lowered, and this

can occur at temperatures much higher than cryogenic temperatures. - Materials exhibiting low-temperature embrittlement should not be used for cryogenic service.

- The large temperature difference between ambient and cryogenic conditions (300° F or more)

results in significant thermal contraction of most materials, which should be accommodated for

in designs for cryogenic service.

Source: Hydrogen Tools. H2tools.org/bestpractices

Meet Deepak Bawa

Mr. Bawa was born and raised in Yamuna Nagar, Haryana – a small town in the north of India – together with his three siblings. He started his technical education with a diploma in mechanical engineering from Govt. Polytechnic, Ambala City and then finished his Bachelors in mechanical engineering from the Sant Lonowal Institute of Engineering and Technology, Sangrur, Punjab in 2003. After working for five years in India, he moved to the USA in 2008 and has since worked in engineering and project management roles for several EPC companies. He has been involved in several megaprojects including LNG, hydrogen, ammonia, methanol, etc, gaining work experience in India, the Middle East, and South and North America. He is currently Director – Project Development

Mr. Bawa was born and raised in Yamuna Nagar, Haryana – a small town in the north of India – together with his three siblings. He started his technical education with a diploma in mechanical engineering from Govt. Polytechnic, Ambala City and then finished his Bachelors in mechanical engineering from the Sant Lonowal Institute of Engineering and Technology, Sangrur, Punjab in 2003. After working for five years in India, he moved to the USA in 2008 and has since worked in engineering and project management roles for several EPC companies. He has been involved in several megaprojects including LNG, hydrogen, ammonia, methanol, etc, gaining work experience in India, the Middle East, and South and North America. He is currently Director – Project Development

with New Fortress Energy, based in Miami, Florida, the USA. Although he has fully settled into life in the USA, he comments that he does miss not being able to spend time with his parents and childhood friends. He maintains a strong connection with and an interest in his mother country, and is indeed very concerned about deteriorating air quality in all the big cities in India as well as the effects of global warming. Mr. Bawa is therefore keen to help the Indian government and other public and private companies in taking the next steps towards decarbonising and improving air quality and climate by using hydrogen as the main fuel.