Unitex Steel Mills contracted Danieli for engineering, manufacturing, procurement, supply, and on-site services for a complete minimill to be installed in the Feni district of Chittagong, in the eastern region of Bangladesh. It will include auxiliary plants for fumes and water treatment as well as the most advanced electrical and automation systems. The new, Danieli MIDA minimill will produce 1 Mtpy of long products including quenched rebars, smooth rounds, equal angles and channels.

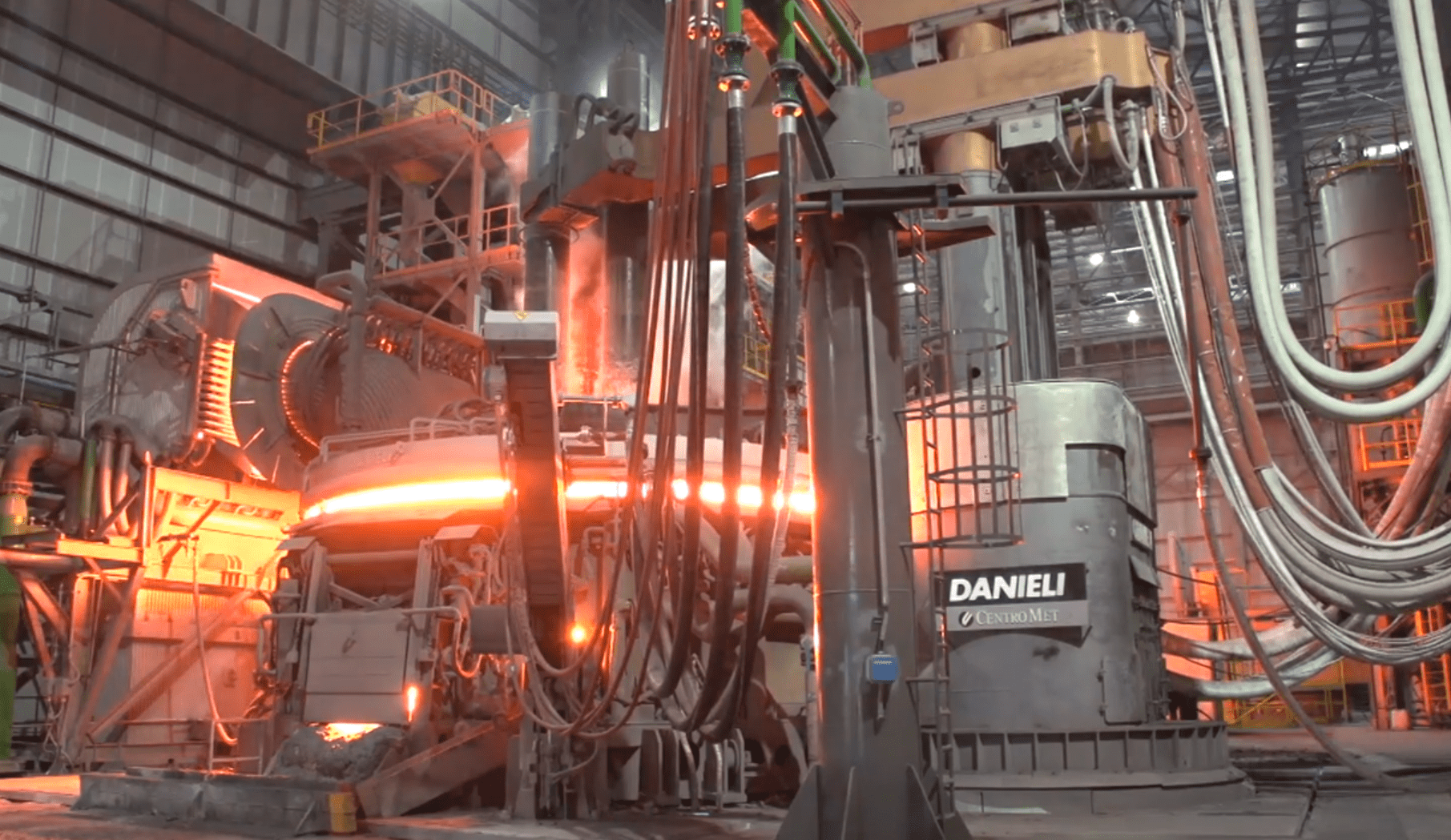

It will operate a highly efficient, 100-t Digimelter featuring Q-One digital power feeder and ECS continuous-scrap charging and preheating systems will competitively melt scrap. Hybrid by design, the Danieli-patented Q-One power feeder provides digital arc-control, for lower electrical energy and electrode consumption, and negligible impact on the electrical grid.

A four-strand, 9-m radius quality conticaster featuring FastCast Cube™ oscillator, Eco-Power Mould™ and EMS, will produce a large variety of low- and medium-carbon grades at high productivity rates, without jeopardizing the quality of the final product. Cast billets will be directly hot-charged in a Danieli Centro Combustion 150 tph walking-beam reheating furnace that will be prefabricated and refractory-lined in the workshop to reduce erection time and costs at site.

The super-flexible merchant rolling mill will feature 18 H, V and convertible H/V stands to guarantee production flexibility and also produce small dimension deformed rounds with multi-slit process up to 6-strands.

The bar finishing facility will feature a 90-m long cooling bed equipped with a water-spray extra-cooling system, and two 12-m long single-head magnetic stackers for profiles Danieli Automation will supply all electrical equipment, including power distribution, as well as the automation and process control systems Level 1 and 2.

The new minimill of Unitex Steel is scheduled to be started up in Q4 2024.