Finnish recycling services provider Konepeikko Oy has awarded Primetals Technologies the contract to supply a new torch-cutting machine for its facilities located at steel producer Ovako Imatra Oy Ab’s premises in Imatra, Finland. This environmentally friendly solution is part of Primetals Technologies’ latest developments in scrap cutting, and is significantly reducing noise emissions.

The scrap cutting machine ensures that Konepeikko Oy is well-positioned to meet the industry’s current and future demand for scrap. The need for effective scrap management systems is increasing, aligning with the transition to green steel production.

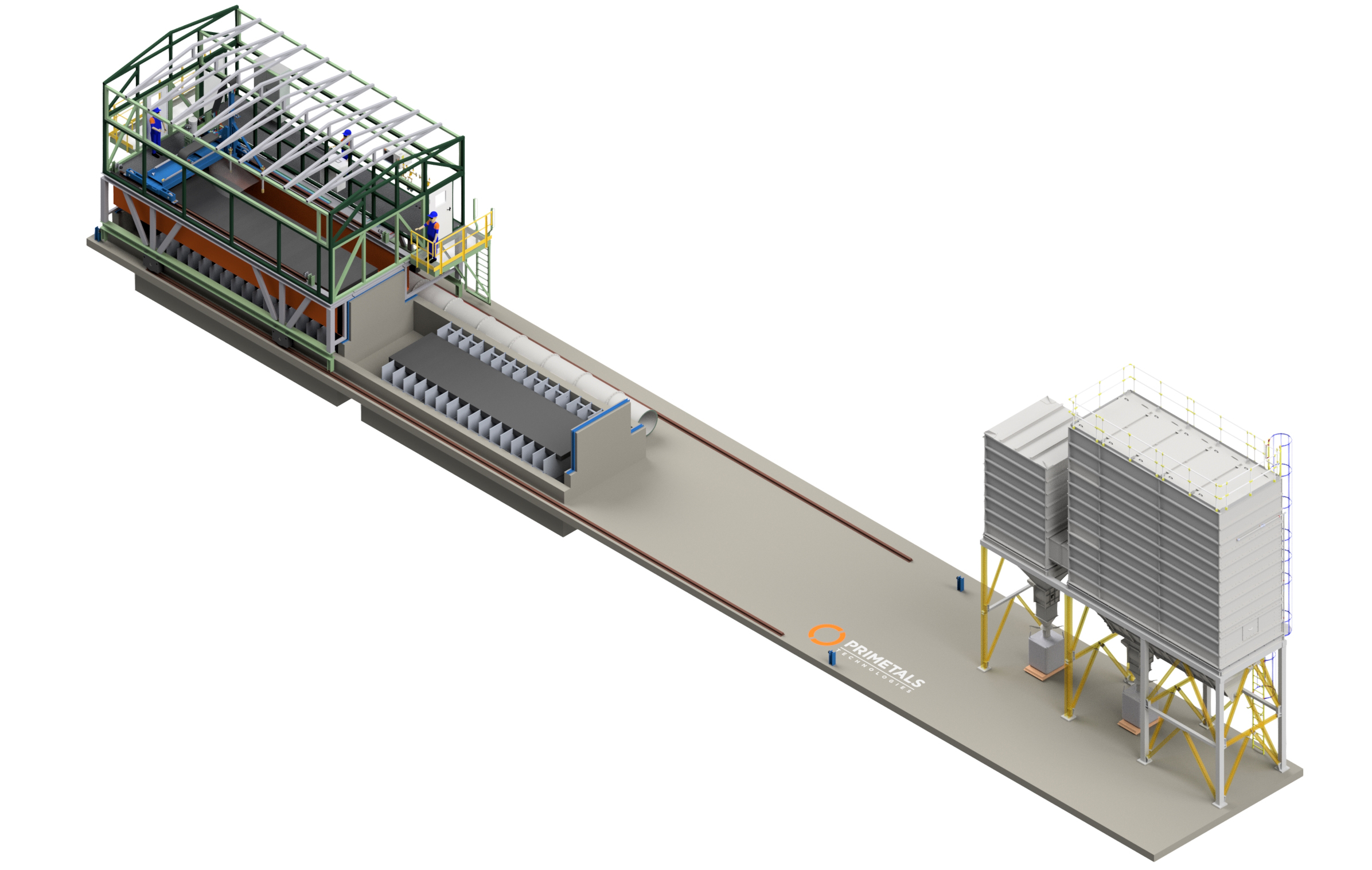

A highly efficient dedusting system ensures that dust emissions from the cutting process remain well below the limits set by environmental regulations. Additionally, the cutting machine is placed inside a moveable cabin, further reducing noise emissions. This new technology enables Konepeikko Oy to comply with stringent Finnish environmental regulations, which was one of the main influencing factors for its decision, along with improved process efficiency and occupational safety.

Operators control the machine at a safe distance from a desk outside the cutting cabin, supported by a video monitoring system. Predefined cutting programs based on recipes simplify operation and reduce processing times.

Konepeikko Oy’s new machine will cut various types of scrap, including billets, blooms, and bundles of rolled bars. Furthermore, the system‘s ability to integrate iron powder into the cutting process allows for cutting of tundish skull, rolling mill rolls, and other hard, high alloy materials.