A German firm specialising in hydrogen fuel technologies has embarked on a strategy to support the production of ‘green steel’ for the first time in the Sultanate of Oman. The landmark initiative, slated for to be operationalised as early as by 2024, has the potential to position the Sultanate of Oman among the world’s pioneering manufacturers of green steel — essentially steel produced with a low-carbon footprint.

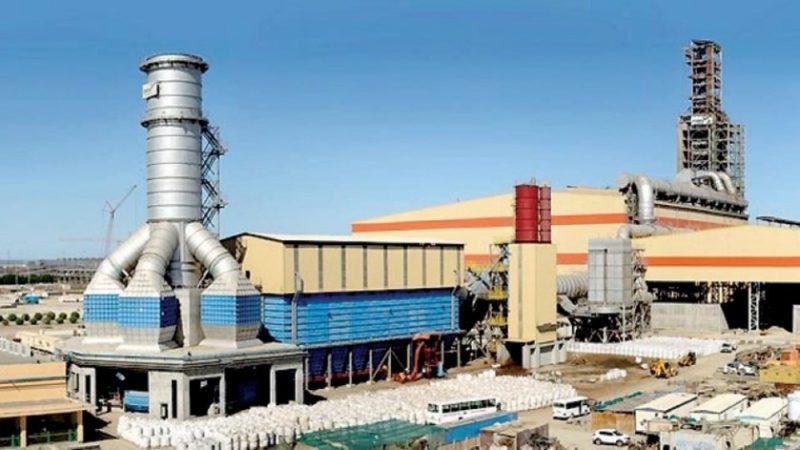

Munich-headquartered Hydrogen Rise AG has unveiled plans to trial the production of green steel at the Sohar Port complex of Jindal Shadeed Iron & Steel (JSIS) using green hydrogen as a low-carbon energy alternative to fossil fuels. The initiative, planned initially as a modest-scale venture, is proposed to be ramped up in the future, according to a key executive.

“I am proud to announce that Hydrogen Rise, Jindal Shadeed Iron and Steel and Sohar Port and Freezone have agreed on evaluating a landmark trial of green hydrogen in the production of environment-friendly steel”, said Olav Carlsen, Co-Founder and CFO – Hydrogen Rise AG.

“Following a techno-economic feasibility study, the first phase will include a bankable starting size of 35MW electrolysis with a possible step by step scaling path to 350MW”, he added in a post on LinkedIn over the weekend. Hydrogen Rise, which has a well-established presence in the Sultanate of Oman, will “develop, build and operate the green hydrogen facility” at Suhar to supply Jindal Shadeed with its energy requirements, Carlsen stated.

“Jindal can become an early pioneer in utilising these innovative decarbonisation technologies to save natural gas, reduce the complex’s carbon footprint and become a major player in the fast developing global market for green steel”, he further noted, adding: “I am very excited to work with Jindal Shadeed and Sohar Port and Freezone to start the evaluation of this project, that could be up and operating by mid-2024.”

The move marks the first, concrete initiative to harness zero-carbon green hydrogen to decarbonise heavy industries in the Sultanate of Oman. Globally, the iron and steel industry accounts for around 8 per cent of total emissions of CO2 – the planet-warming gas. It ranks only second to the power generation sector as the biggest industrial producer of greenhouse gases.

In 2020, the German firm set up Hydrogen Rise LLC in the Sultanate of Oman with the goal of creating joint ventures with Omani private investors to plan, develop, build and operate green hydrogen production plants in the country. Earlier, in partnership with the German University of Technology in Oman (GUtech), Hydrogen Rise set up the Oman Hydrogen Centre to support learning and R&D.

Significantly, the proposed partnership with Jindal Shadeed, the largest privately-owned integrated steel producer in the GCC, augurs well for its ambitions to become a low-carbon manufacturer of steel. Launched in 2010 with an investment of around $1.1 billion, the plant has a current annual steel production capacity of 2.4 million tonnes. The Sohar Port complex includes a 1.8 MTPA gas-based Direct Reduced Iron (DRI) Plant which produces Hot Briquetted Iron (HBI) and Hot DRI (HDRI), and a 1.4 MTPA Rebar Rolling Mill with ‘state-of-the-art technology.